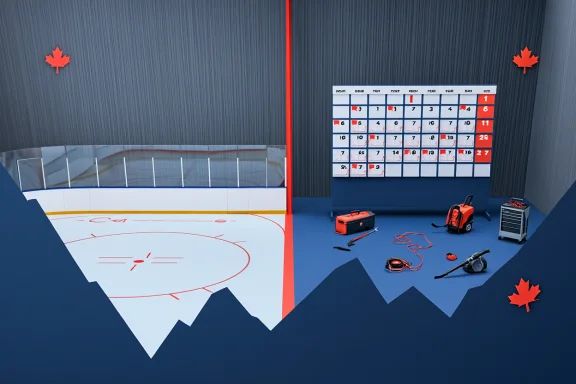

Maintenance Scheduling Integration: Balancing Operations and Upkeep

Picture this: It’s a crisp Saturday morning in February, and your hockey rink in Winnipeg is booked solid from 6 AM to midnight. But your ice resurfacing equipment just started making that concerning grinding noise that means trouble’s brewing. Sound familiar? If you’re managing a sports facility anywhere from Victoria to St. John’s, you’ve likely faced this exact dilemma – when do you squeeze in essential maintenance without losing precious revenue?

The challenge hits Canadian facilities particularly hard. Our shorter outdoor seasons mean indoor facilities carry the load for months, while extreme weather from prairie blizzards to Maritime storms can wreak havoc on scheduling. The good news? Smart maintenance scheduling isn’t just about avoiding disasters – it’s about creating a system that actually boosts your bottom line.

Understanding the Canadian Facility Maintenance Challenge

Canadian sports facilities face unique pressures that make maintenance scheduling more complex than our southern neighbours might realize. Take ice rinks, for instance – they’re running overtime from October through April, with little downtime for major repairs. Meanwhile, outdoor tennis courts in places like Calgary might get eight good months before winter storage becomes necessary.

According to recent industry data, facilities that implement strategic maintenance scheduling see 15-20% fewer emergency shutdowns and maintain 8% higher customer satisfaction rates. That’s significant when you consider the average community centre in Canada serves 2,000-3,000 members annually.

The seasonal reality means Canadian facility managers must think months ahead. While facilities in Phoenix can spread maintenance year-round, a curling club in Saskatoon has a narrow window between seasons to tackle major projects.

Strategic Timing: When to Schedule What

Peak Season Maintenance (The Art of Threading the Needle)

During prime booking seasons, focus on maintenance that can happen during natural gaps. Most Canadian facilities see lulls between 1-4 PM on weekdays and late Sunday evenings. This is your golden window for:

- Equipment calibration and minor adjustments

- Surface cleaning and spot repairs

- HVAC filter changes and basic system checks

- Lighting maintenance (especially important during our long winter months)

Smart facility managers in places like Toronto’s community centres have started offering “maintenance discounts” – reduced rates for bookings during traditionally slow periods, which creates predictable downtime slots.

Shoulder Season Strategies

The transition periods – late spring and early fall – offer your best opportunities for major maintenance projects. This is when you tackle:

- Deep cleaning and facility deep-dive inspections

- Major equipment overhauls

- Court resurfacing projects

- Structural repairs and painting

A successful approach used by facilities across Canada involves creating “maintenance partnerships” with regular users. Hockey leagues in Edmonton, for example, often coordinate their own off-season around facility maintenance schedules, creating win-win scenarios.

Off-Season Overhauls

When winter finally releases its grip or outdoor season winds down, that’s your time for the big projects:

- Complete system replacements

- Facility renovations and expansions

- Major surface work (think tennis court resurfacing or track replacement)

- Technology upgrades and integration projects

Technology Integration: Your Secret Weapon

Modern Canadian facilities are leveraging digital tools to optimize maintenance scheduling like never before. Predictive maintenance software can analyze usage patterns and environmental factors specific to Canadian conditions – like how humidity changes from Toronto’s summer heat to winter dryness affect wooden court surfaces.

Smart Scheduling Systems

The best maintenance scheduling platforms now integrate with booking systems, automatically identifying optimal maintenance windows. They consider factors unique to Canadian operations:

- Weather-related booking pattern changes

- Seasonal sport transitions

- Holiday and long weekend impacts

- Regional event schedules (like March Break variations across provinces)

Data-Driven Decision Making

Facilities using integrated scheduling report 25% better resource allocation and 30% fewer scheduling conflicts. The key is tracking metrics that matter:

- Equipment usage hours vs. manufacturer recommendations

- Customer complaint patterns related to facility conditions

- Revenue impact of maintenance-related closures

- Seasonal wear patterns specific to your climate zone

Building Your Maintenance Schedule Framework

The 90-Day Planning Cycle

Successful Canadian facilities operate on quarterly planning cycles that align with our distinct seasons. Here’s a framework that works:

Three-Month Outlook: Plan major maintenance projects with full awareness of upcoming peak periods. A ski club in Whistler, for example, schedules lift maintenance in late spring, knowing summer mountain biking season is less equipment-intensive.

Monthly Reviews: Assess immediate needs and adjust schedules based on usage patterns and equipment performance.

Weekly Execution: Focus on immediate tasks and emergency response capabilities.

Communication is Key

Your maintenance schedule affects everyone – staff, members, and community users. Implement a communication strategy that includes:

- Advance notice periods (minimum 2 weeks for regular users, 4 weeks for leagues)

- Clear explanation of maintenance benefits

- Alternative scheduling options when possible

- Regular updates during extended maintenance periods

Cost-Effective Maintenance Strategies

Preventive vs. Reactive Approaches

Canadian facilities operating on tight municipal budgets or membership fees need to maximize every dollar. Preventive maintenance typically costs 60% less than emergency repairs, and the numbers are even more favourable when you factor in lost revenue from unexpected closures.

Consider partnering with local technical schools or community colleges. Many HVAC and mechanical programs need real-world training opportunities – a win-win that’s particularly popular with facilities in university towns like Kingston or Fredericton.

Seasonal Bulk Purchasing

Take advantage of Canadian seasonal patterns by coordinating maintenance supply purchases. Buy ice rink equipment in summer, tennis court supplies in fall, and HVAC components during shoulder seasons when demand is lower.

Emergency Response Integration

No maintenance schedule survives contact with a Canadian winter storm or equipment failure during a championship tournament. Build flexibility into your system:

- Maintain relationships with 24/7 emergency service providers

- Keep emergency supplies on hand for common seasonal issues

- Develop contingency plans for different scenarios

- Train staff to handle common maintenance issues

The most successful facilities create “emergency protocols” that can temporarily adjust the regular maintenance schedule while maintaining safety and basic service levels.

Making It Work: Real Success Stories

Facilities across Canada are proving that strategic maintenance scheduling isn’t just about keeping the lights on – it’s about creating competitive advantages. Community centres that master this balance report higher member satisfaction, fewer complaints, and surprisingly, increased booking revenue as word spreads about consistently well-maintained facilities.

The key insight from successful facilities? Maintenance scheduling isn’t a necessary evil – it’s a strategic tool for building member loyalty and community reputation. When your courts are always in top condition and your equipment runs smoothly, members notice. They book more sessions, renew memberships, and recommend your facility to others.

Start by auditing your current maintenance patterns and booking data. Look for natural maintenance windows you’re not currently utilizing, and begin implementing predictive scheduling for routine maintenance. Remember, every hour of planned maintenance during slow periods can prevent hours of lost revenue during peak times.

Your facility’s success depends on finding that sweet spot between operational excellence and revenue optimization. With the right approach, maintenance scheduling becomes less about choosing between revenue and upkeep, and more about maximizing both.